Five years of innovation: Six Swiss startups share their journeys

This year, Swiss Food & Nutrition Valley turns five. On 2nd October, we’ll be celebrating in style with friends from across the ecosystem. We’ve invited six of our startups to share their vision for the future – from brain food and air-based protein bars to plant-driven food systems. But before we dive into their predictions, let’s take a closer look at their journeys so far. Read on – or click on the links below – to discover their stories.

Voltiris | Food For Labs | Food Young Labs | Go Nina | Nereid Water | Vivent

Dominik Blaser, Voltiris

What was the very first inspiration or “aha moment” behind Voltiris?

We founded Voltiris in 2022 with the aim of making greenhouses more productive and energy-efficient. Our co-founder, Jonas Roch, was struck by a simple observation during his PhD: plants are green because they don’t absorb all wavelengths of light. That led to the idea that the unused part of sunlight could be separated and converted into clean energy – without compromising growth.

What milestone from the last five years felt like a key turning point?

Our recent flagship installation at Meier Gemüse in Aargau. This project was the first time everything came together: large-scale installation, financial structuring, and full system-level energy production. It was the moment our vision turned into a tangible new model for how agriculture can generate and manage its own clean energy.

What’s the most exciting way your technology is being applied today?

Beyond producing renewable, grid-independent energy at a lower cost than alternatives, we’re seeing strong benefits for growers. Crops stay cooler while still receiving all the light they need for photosynthesis. As summers become increasingly hotter, this dual advantage – energy plus climate resilience – has proven extremely exciting for growers across many crop types.

At SFNV’s 5th anniversary event, I’ll be sharing my vision for a future where all crops are produced in controlled environments. I look forward to sharing it with you!

Raphael Thurn-Taxis, FoodFor Labs

What sparked your interest in brain-focused nutrition?

Our journey began with a simple but powerful idea: what if food could fuel our minds as well as our bodies? We were all working intense jobs and long hours, and were disappointed with what the market offered – coffee, energy drinks, pills. The science was already much further along, so we decided to create the strongest ultra-functional convenience product: something instant that actually helps mental athletes perform.

What did your very first experiments or product tests look like?

We tested the first prototypes ourselves and loved the results. Friends quickly got curious and tried them too. That’s when we started structured focus groups at workplaces and universities, always with our core customer in mind: the mental athlete.

How is FoodFor Labs engaging customers or partners today?

We combine two things: on the ground, we run sampling and partnerships at workplaces, gyms, and events. Online, we build a community with our mental athletes through content, direct sales, and social media. This way, we’re close to our customers wherever they need us.

What are you most proud of?

The team. Building something like FoodFor only works when people bring in different skills, push each other, and stay committed to the vision. That’s our biggest asset!

At the 5th anniversary event, I’ll be talking about cognitive shots and how to combat mental fatigue in today’s fast-paced world.

Abouzar Rahmani, Food Young Labs

What inspired you to start FoodYoung?

FoodYoung’s roots lie in my Persian family heritage, where farms and factories shaped an early connection to food production. I founded FoodYoung in 2012 with a personal mission: to create food that is clean, nourishing, and actually tastes good.

How has your offer evolved in the last few years?

Five years ago, we were working in a much smaller facility producing dried fruit and nut mixes. With just one production line, a small lab, and a 5kg chocolate melangeur, we began experimenting with making cleaner chocolate. Cereals, baked goods, spreads and frozen meals followed. Each step rebuilt familiar products into cleaner, healthier, and more sustainable versions. From this, the idea of a food innovation lab was born. In 2024, we opened FoodYoung’s state-of-the-art innovation facility in Balerna.

What do you offer your customers today?

The lab operates as a full-stack food innovation studio – from formulation to pilot to scale – combining culinary craftsmanship with food science, advanced machinery, AI insights, and a strict clean-label commitment. In parallel, we are building our own products to test the market directly, with a portfolio of more than 100 commercially ready recipes. Most recently, we launched a first-of-its-kind online product creation tool that allows innovators to design a product from scratch and see it ready to launch in six weeks.

What are you most proud of?

What I’m most proud of is transforming FoodYoung from a small facility into a full-stack food innovation lab — a dynamic ecosystem where entrepreneurs, scientists, chefs, and companies come together to reimagine food from idea to scale and create products that shape the future of how we eat.

At SFNV’s anniversary event, I look forward to showcasing protein bars made out of air! I’ll also share my vision for the future of food. Let’s shape it together.

Richard Lichtenberg, GoNina

Do you remember when you realised food waste was a problem you wanted to solve?

When we spoke with bakeries, the pattern was always the same: existing solutions focused on selling or redistributing surplus after it occurred. The real gap was earlier in the chain. Businesses lacked the tools to predict demand. We wanted to change that by tackling waste at its source. So GoNina started in bakeries, where the waste was visible every evening. Trays of unsold bread and pastries went straight into bins.

What made you decide to tackle it with AI-driven forecasting?

Demand depends on so many factors – weekday patterns, weather, holidays, local events – which are far too many for manual planning. AI models are built to handle exactly this type of pattern recognition. Once we saw that transaction data was already available in POS systems, it was clear we could train models adapted to each location and product.

What did your earliest prototype look like, and who tested it?

We were lucky to have a large bakery chain agree to test our product early on. Their scale and feedback helped us to refine the model much faster. Each week we added more products, checked the outcomes against real sales, and adjusted the system. That direct feedback loop with both small and big bakeries shaped the product into something practical.

How are food businesses using GoNina today?

We now have paying customers and are scaling across Switzerland, while constantly fine tuning the product. Each new partner adds data and insights that make the forecasts more accurate. Instead of guessing demand for the next day, store managers use our AI Forecasts to see recommended production volumes.

What are you particularly proud of?

I’m proud that we moved into daily operations of food business across Switzerland. More and more vendors rely on GoNina every day and it’s great to see us creating a real impact. Equally, I’m proud that the solution works for small vendors as well as larger chains. It shows that our technology can directly cut waste where it happens.

At the 5th anniversary event, we’ll be sharing our visions for 2050 and more on how we’re reducing food waste through accurate and real-time forecasting.

François Frigola, Nereid Water

What first motivated you to work on water and food access?

Climate change and unchecked industrialisation are draining and polluting our soils,driving droughts that disrupt agriculture worldwide. We envision a future where everyone has access to safe, sustainable water sources, without harming the environment. Nereid’s distillation technology replicates the natural water cycle: evaporation at ambient pressure and low temperature followed by condensation.

How did you test your first prototypes – and what did you learn?

We developed 5 prototypes to test all POCs and materials in real-world conditions and we learned that industrialisation is a heavy challenge. Technology watch and intelligence is crucial.

Everything started with the idea, inspired by nature, of combining solar and sea energy and portable systems to provide clean water and grow food in remote areas. The model is completely autonomous through biomimicry, designed to be as resilient as nature itself.

Where are your systems currently being piloted?

At the moment it’s being tested at our logistics facilities on the military naval base of Saint-Mandrier-sur-Mer (Toulon) with the support of the French authorities. The 5 m³ pre-commercial series is soon set to be deployed at our partners’ facilities, allowing us to finalize the POC and further optimise material studies.

What have you learnt so far?

Something simple and profound: that true impact comes when innovation, industry, and politics work hand in hand. Collaboration is really everything.

I look forward to joining the anniversary celebration to share our vision of how solar-powered systems can secure water and food in even the most remote places.

Carrol Plummer, Vivent

What inspired you to learn to listen to plants?

We were motivated by the idea that plants already know what they need – they just aren’t able to share it with us. The information network inside plants works even if branches are cut off or roots are severed. Climate change, water scarcity, and the desire to produce more food sustainably led us to ask: what if we could hear what plants are saying? This vision motivated us to explore the hidden “language” of plants, and see if decoding these signals could help growers make better, faster decisions while reducing waste.

What was the very first experiment that showed you plants could “talk”?

Like Darwin and Indian scientist Jagadir Chandra Bose before us, we started with the Venus flytrap, and then replicated work from the world’s leading plant electrophysiology expert at the University of Lausanne. We can now tell the difference between aphids and a thrips attacking tomatoes, see evidence of fungal infections well before visual symptoms appear or have a crop turn on its irrigation system itself.

What was the transition point between research and creating a company?

The transition happened when we moved from proof-of-concept in the lab to real-world trials with growers. Farmers and ag input companies began asking if they could use our technology in their fields and greenhouses. That demand drove us to found Vivent Biosignals as a company – transforming our research into robust, commercial tools now deployed in potatoes, berries, vines, and controlled-environment crops.

Who’s using Vivent’s technology today, and what impact are you seeing?

We’re currently working with around 200 clients across the agri-food value chain. Breeders use our technology to accelerate the development of more resilient varieties, while agrochemical and biostimulant companies rely on our sensors to demonstrate product efficacy. Farmers of high-value crops use Vivent’s tools to improve yields and crop quality. Across these groups, the impact is clear: earlier warnings of stress, more precise control of irrigation and inputs, and stronger evidence for sustainable practices.

What achievement are you particularly proud of?

We’re especially proud of turning a bold idea – listening to plants – into a practical tool that’s transforming how crops are grown. It’s remarkable to see our technology helping to produce food more efficiently and sustainably. We’re also proud of the collaborations we’ve built, from innovative farmers to leading universities and global ag input companies and to other entrepreneurs.

At the 5th anniversary event, I’ll share my vision for a plant-driven food system – now that we have the tools to understand what plants are saying. I look forward to hearing your reactions!

Are you a Valley partner?

Join us at our 5th anniversary celebration on 2nd October!

Latest News

Scale-up Vaud announces the 44 companies newly labelled for 2026

Scale-Up Vaud celebrates its 10th...

OneAgrix holds USPTO patent-pending status for agentic AI trade infrastructure supporting regulated global food supply chains

Valley partner, OneAgrix, a Swiss- and...

HES-SO Valais-Wallis brings together European experts for extrusion training focused on food technologies

Valley partner HES-SO Valais-Wallis,...

Agroscope’s new work programme places a greater focus on impact and practical benefits

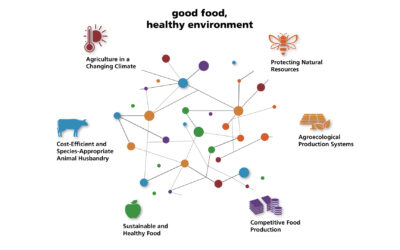

Agroscope’s 2026-2029 Work Programme...