5 questions on side stream valorisation for UpGrain CEO Vincent Vida and COO William Beiskjaer

Side stream valorisation is all about finding new ways to transform by-products from food processing waste streams into new, high-value products. This approach isn’t just about sustainability – it’s about smarter resource use, cross-industry collaboration, economic growth, and a more resilient food system.

There are many Swiss companies already active in this space – and we look forward to hearing from many of them at our forthcoming State of Play on side stream valorisation.

In the meantime, we sat down with one of our speakers, Vincent Vida, CEO and Founder of UpGrain, and William Beiskjaer, COO and Co-Founder of UpGrain, to get to know more about their work and to chat about the role of collaboration in accelerating side stream valorisation’s potential.

What introduced you to the world of side stream valorisation?

Vincent: Everything started with a brewery tour! I was struck by the sheer amount of spent grain left over after beer production – an untapped resource with incredible potential. Inspired to make a change, I began developing the technology to transform this by-product into valuable ingredients.

William: When I joined the team, we continued to push this vision forward. Thanks to a partnership with Brauerei Locher, a family-owned brewery, we were able to establish our first production facility. Today, it’s the largest food upcycling plant in Europe.

Could you tell us a bit about UpGrain’s mission and work?

Vincent: At UpGrain, we are committed to transforming brewing byproducts into something even more valuable. In the face of climate change and the growing need for better nutrition, our mission is to bridge sustainability and health to create real impact. Our upcycling process requires no additional resources, land, or water, making it a truly circular solution. Our products are also packed with essential nutrients, including proteins, fibres, vitamins, and minerals, contributing to a healthier and more sustainable food system. The ingredients we produce can be used in a number of applications from baked goods to breakfast cereals, meat alternatives, pasta, snacks and protein bars – to name just a few!

What is it like to innovate as part of Switzerland’s food ecosystem?

William: Switzerland is a real hub for innovation, particularly in food tech and sustainability. In the last few years, we’ve benefited from the support and opportunities provided by the Swiss government, which has played a key role in driving our growth and advancing our mission. We’re especially proud to have our headquarters in Appenzell – a place that not only offers stunning views but also provides the perfect environment for innovation and collaboration. The region’s commitment to sustainability, circular economy principles, and high food standards aligns perfectly with our vision. With strong support from research institutions, industry leaders, and food innovation networks, we are excited to continue driving change from the heart of Switzerland.

You’ve recently kicked off an exciting new collaboration with Bäckerei Böhli AG, a well-known bakery and confectionery company. Could you tell us about how you’re teaming up?

Vincent: We partnered with Böhli as part of the NRP (Neue Regionalpolitik) project, supported by the canton of Appenzell Innerrhoden and the Swiss government. This initiative allows us to explore how our ingredients can be integrated into various product applications. While we’ve already tested numerous recipes and possibilities, our raw material is still relatively new, and we’re still uncovering its unique properties. That’s why our collaboration with Bäckerei Böhli AG is especially exciting. We’re working together to create innovative, nutritious, and delicious products, while getting insights on our products and their applications. We’re also constantly looking for new partnerships, including an upcoming collaboration with a pasta producer, which we look forward to unveiling soon.

Where do you see the upcycled food industry in five years?

William: In five years, I see UpGrain playing a key role in shaping the future of upcycled food ingredients. Sustainability and health will be major focus points in the food industry, with more manufacturers integrating ingredients that align with these values. I think brewer’s spent grain (BSG) will become a staple ingredient across various food categories, recognised for its nutritional value and environmental benefits. At the same time, clearer regulations, certifications, and labeling standards will make it easier for consumers to recognise and trust upcycled foods. Our products fit perfectly into this shift, offering both sustainability and nutrition while delivering great taste and quality. Personally, I hope that UpGrain can continue to contribute to this movement and help to set new benchmarks for sustainability in the food industry.

Join us at our State of Play on side stream valorisation

Vincent and William will be speaking at our next State of Play event on 18 March. Join them to meet and mingle with Swiss innovators and discover how companies can use their insights to create more sustainable business models.

Never miss a Swiss food innovation morsel.

Latest News

Scale-up Vaud announces the 44 companies newly labelled for 2026

Scale-Up Vaud celebrates its 10th...

OneAgrix holds USPTO patent-pending status for agentic AI trade infrastructure supporting regulated global food supply chains

Valley partner, OneAgrix, a Swiss- and...

HES-SO Valais-Wallis brings together European experts for extrusion training focused on food technologies

Valley partner HES-SO Valais-Wallis,...

Agroscope’s new work programme places a greater focus on impact and practical benefits

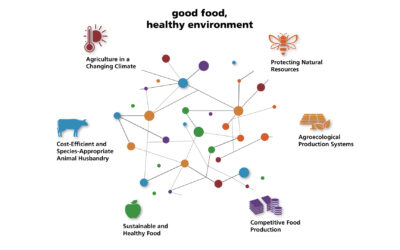

Agroscope’s 2026-2029 Work Programme...