Vivent Biosignals, the Swiss-based...

The Swiss FoodTech Ecosystem Report 2025 maps key trends shaping the future of food in Switzerland

The Swiss FoodTech Ecosystem Report 2025 maps key trends shaping the future of food in Switzerland

Swiss Food & Nutrition Valley (SFNV) and Porsche Consulting have released the Swiss FoodTech Ecosystem Report 2025 to guide the future of Swiss food innovation, combining research data with insights from eight leading experts.

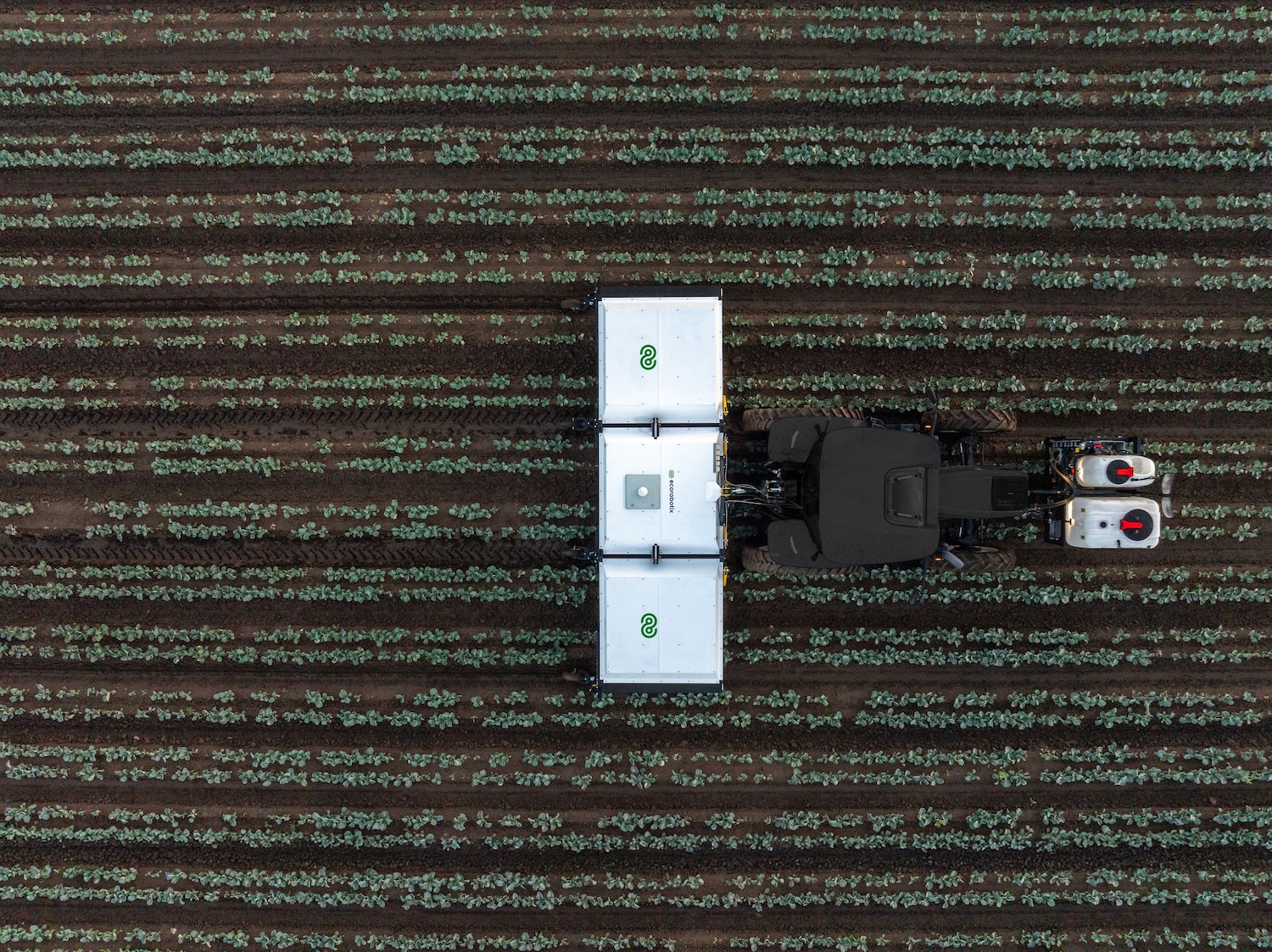

The report reveals that the Swiss FoodTech startup ecosystem has grown by 63% since the last edition in 2021, with many companies developing innovations in the areas of novel ingredients, smart farming, precision nutrition and waste management.

It also shares the three factors that have driven Switzerland’s success as a food nation so far, four global trends shaping the food market today, insights from eight leading food innovation experts and three emerging trends set to drive food innovation by 2030.

It takes an ecosystem

Commenting on the report, Christina Senn-Jakobsen, CEO of Swiss Food & Nutrition Valley said, “It takes an ecosystem to raise a company, just as it takes a nation to create an Olympian. This report captures a snapshot of the innovators, entrepreneurs, and experts working together to build a more future-proof food system, as well as exploring some exciting trends that will define the way we eat in 2030.”

“We can’t change the world alone. Every innovation begins with people who share the same dream,” said Giulio Busoni, Partner at Porsche Consulting. “This report offers a glimpse into a future where science, entrepreneurship, and passion come together to shape a smarter, more human, and more sustainable food ecosystem.”

Five years of collaboration, innovation and impact

The report was teased at Swiss Food & Nutrition Valley’s anniversary celebration earlier this month, marking five years of cross-sector collaboration to accelerate sustainable food innovation. The team took the opportunity to connect with their network of 150+ partners from across the Swiss value chain – from large enterprises, retailers, and academic institutions to cantons, SMEs and startups.

The Swiss FoodTech Ecosystem Report 2025 proves that Switzerland may be small in size, but it continues to demonstrate how collective action can accelerate innovation.

About Swiss Food & Nutrition Valley

Swiss Food & Nutrition Valley (SFNV) is a purpose-driven not-for-profit association, founded in 2020. It brings together the Swiss agrifood ecosystem to pioneer future-proof food systems that are good for the planet, good for people, and good for the economy.

Today, SFNV represents more than 150 partners across Switzerland, from large enterprises, retailers, and academic institutions to cantons, SMEs and startups. We’ve built an open and trusting culture, grounded in the core values of courage, commitment, and collaboration, and driven by purposeful impact.

About Porsche Consulting

Porsche Consulting is a leader in strategic and operational consulting. Founded in 1994 following Porsche’s successful transformation into one of the most profitable and admired luxury sports car manufacturers.

Today, its experts support companies around the world in strategic transformation and performance management. The consultants operate in various sectors ranging from mobility to pharmaceuticals, industrial goods to financial services, energy to aerospace, construction to consumer goods. The main areas of expertise are strategy and organization, brand and sales, development and technology, as well as operational excellence. Porsche Consulting has offices in Germany, Italy, France, China, Brazil, and the United States.

Want to get the latest Swiss food innovation news, events and job opportunities in your inbox?

Latest News

Vivent biosignals raises €7.5M including investments from agri investment fund, horticoop and Pymwymic.

catchfree beats four other exceptional Swiss startups to be crowned winner of the Igeho Rising Star Award 2025

catchfree has been named winner of the...

Cosaic and Ingredion announce strategic partnership to redefine the future of ingredient innovation

Ingredion Incorporated has announced a...

Bühler awards innovators tackling cocoa shortages

Valley partner Bühler has announced...