EPFL’s Prof. Jeremy Luterbacher on turning plants into plastic

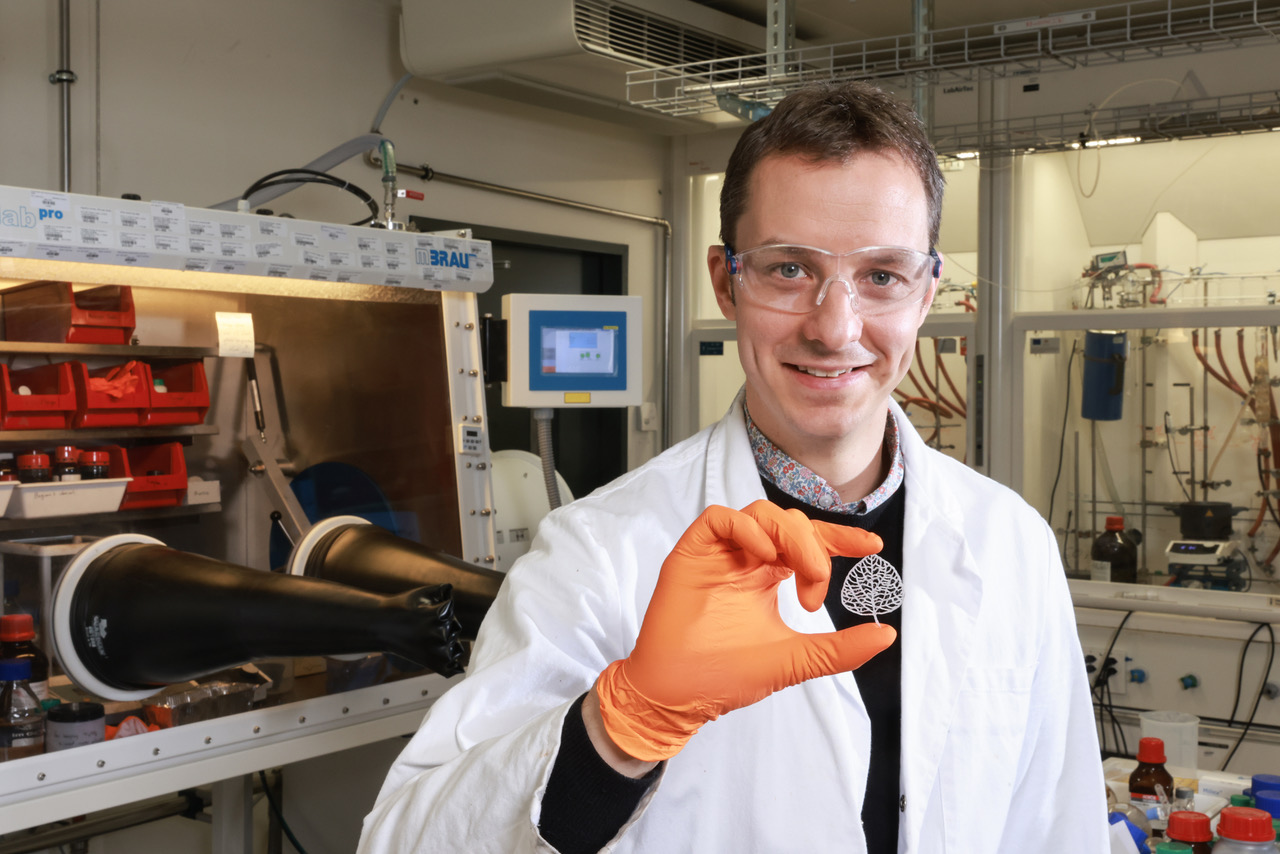

Prof. Jeremy Luterbacher from EPFL’s Laboratory of Sustainable and Catalytic Processing has developed a way to turn plant by-products into materials that could serve as an alternative to some types of plastic.

Researchers at EPFL found that some types of sugar are particularly well-suited to functionalization reactions. One sugar – xylose – is ideal, and plant residue contains a lot of it – up to 20–30%. This means that by using functionalization reactions, they can produce 300 grams of bioplastic out of one kilogram of corn cobs.

“It must be because I’m a chemist, but I find functionalization reactions fascinating. They involve adding a functional group to a chemical compound in order to give it additional properties, but without changing its base structure. These reactions are fairly easy to perform and consume little energy and other resources. You don’t have to break down complicated chains.”, commented Jeremy Luterbacher from EPFL’s Laboratory of Sustainable and Catalytic Processing.

A wide range of applications

The process for producing bioplastic from xylose is simple to carry out and it employs materials that are readily available. It doesn’t alter the base xylose molecules, meaning that as the bioplastic degrades, it simply releases the sugar – which is harmless to the environment.

The resulting material is both tough and heat-resistant and could be used in a variety of application. It can be manufactured as a film, as thread for making fabric or fishing nets, or rolled up in spools for use with 3D printers. It can also make polyesters and polyamides such as nylon with excellent properties, sometimes even better than those made from petroleum-based products. Food packaging could be another application, but the material still needs to go through various certification processes.

Bringing the bioplastic to market

To bring the bioplastic to market, EPFL need to be able to manufacture it at a competitive cost. This would mean around half the price of existing bioplastics and on par with petroleum-based plastics. But their estimates show that this is possible.

“The leaf I’m showing here illustrates the vast potential for our bioplastic. You can see that it allows for extreme precision for producing objects of all kinds. We’re right at the beginning of our journey and we still have a lot of work ahead of us, both in the research lab and with Bloom Biorenewables, a startup we founded to market the technology coming out of our lab. But that just makes our work all the more exciting!” concluded Jeremy.

Never miss a Swiss food innovation morsel.

Latest News

Nestlé and IBM leverage AI and deep tech to unlock new packaging innovations

Valley partner, Nestlé R&D has...

GoNina secures new funding from the Migros Pioneer Fund in its mission to reduce food waste

Swiss foodtech startup GoNina has...

Bühler Scale-Up Day accelerates industry and start-up collaboration

Valley partner Bühler is making...

What if talent – not tech – is the missing ingredient in building food system resilience?

What if talent – not tech – is the...